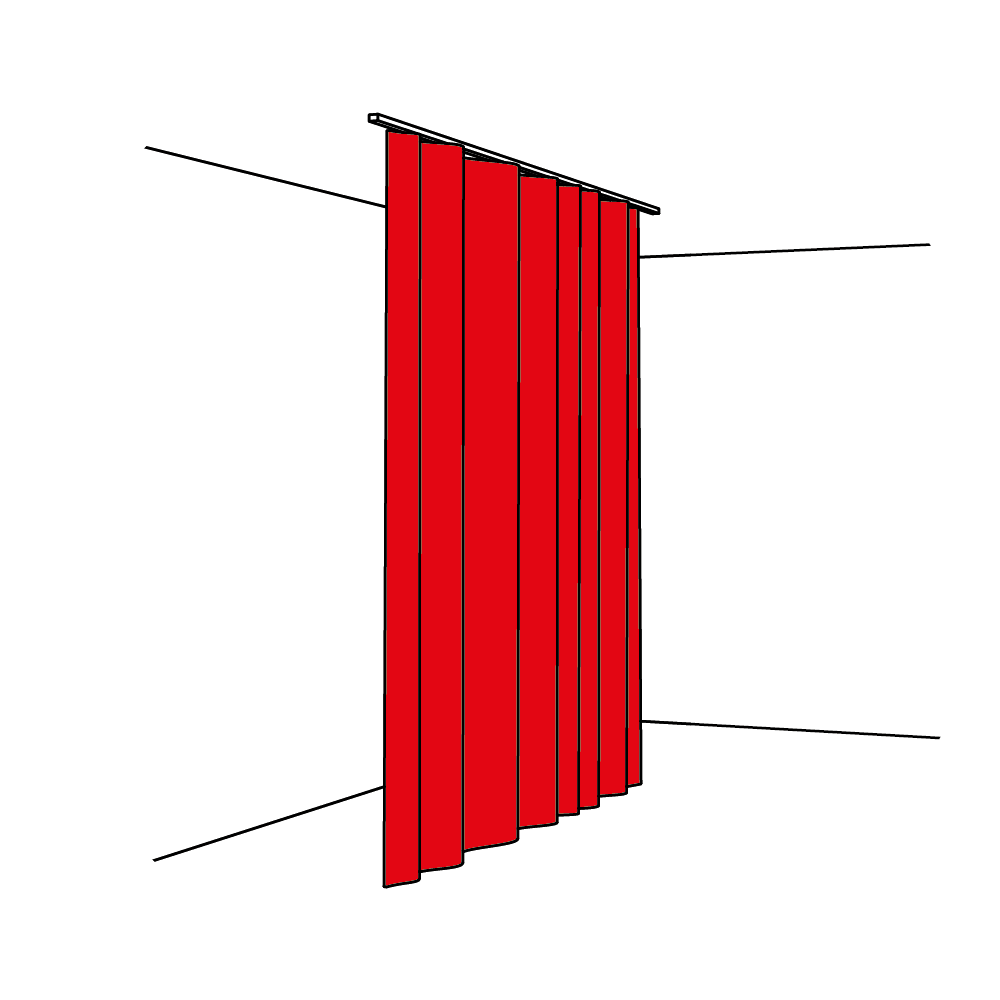

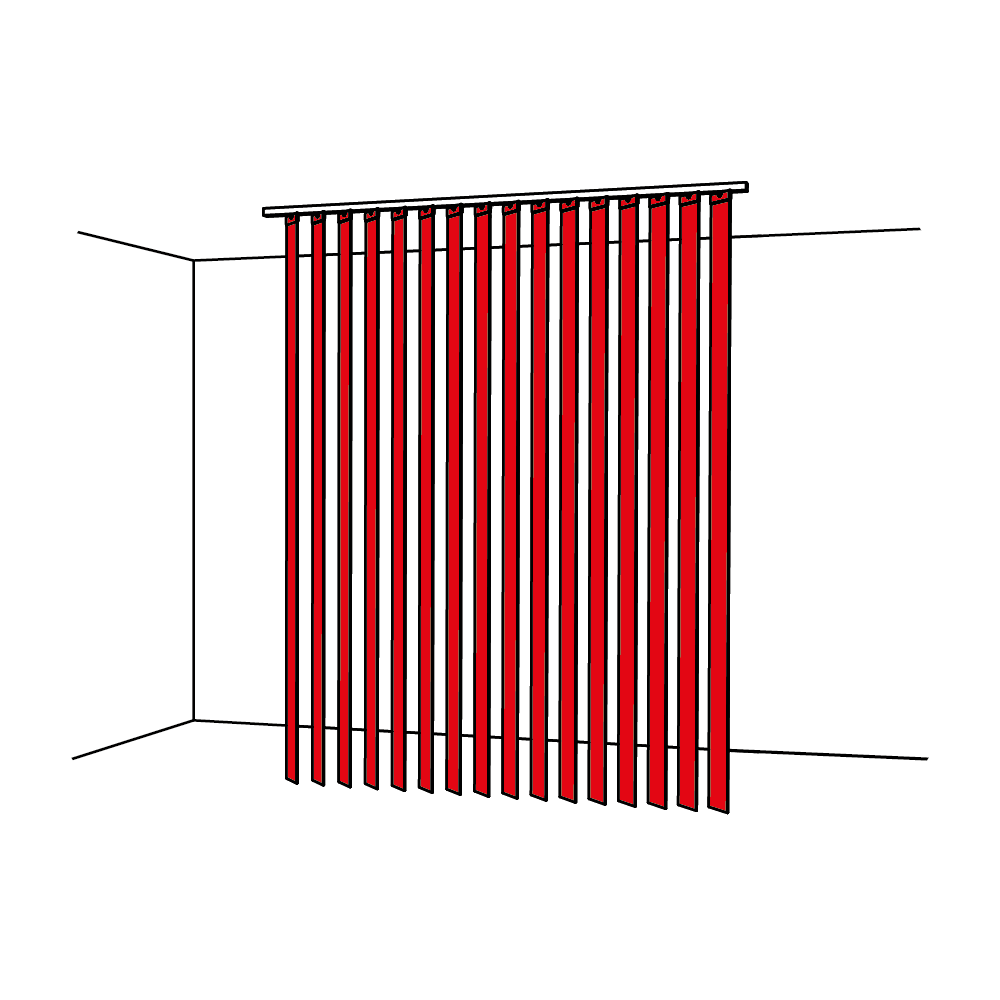

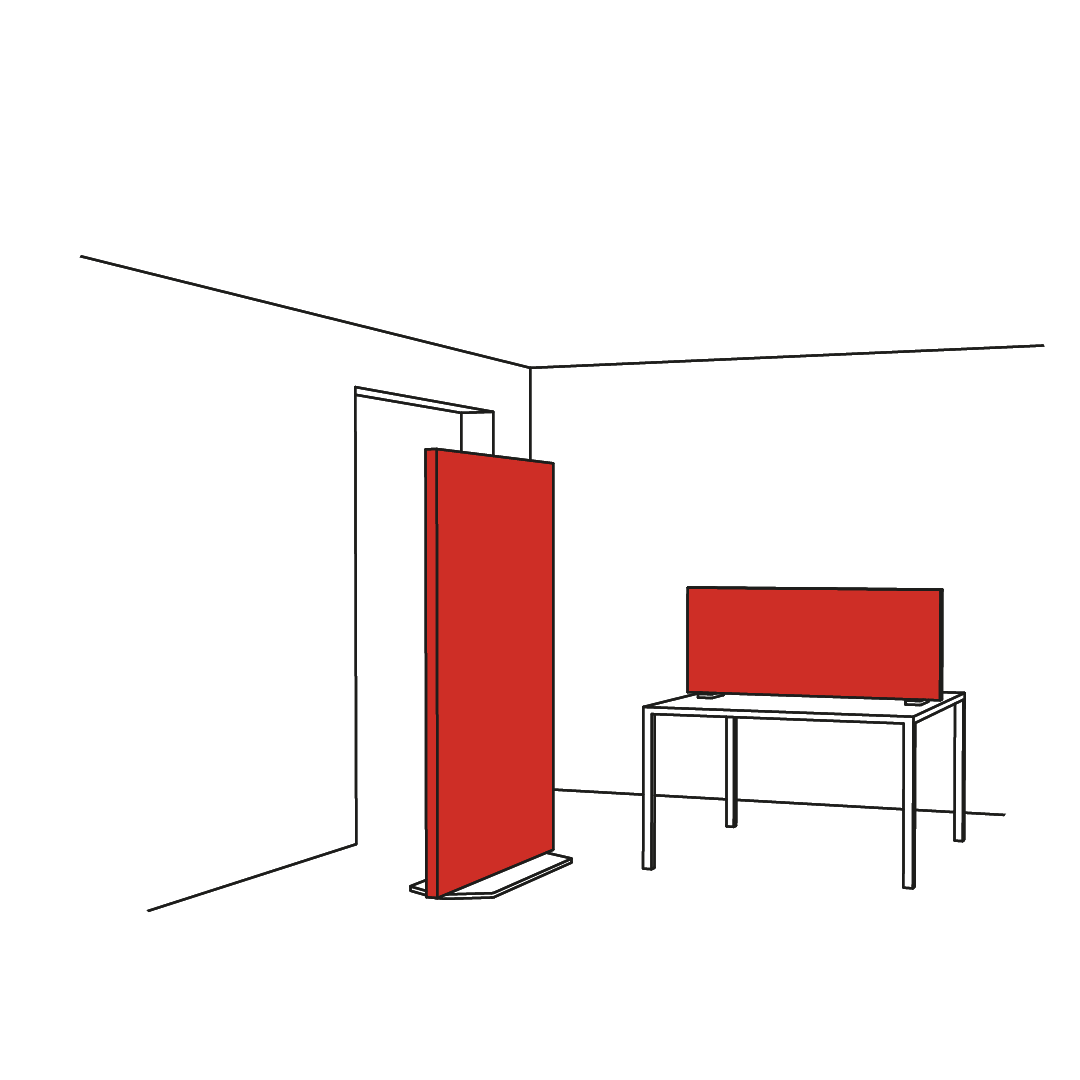

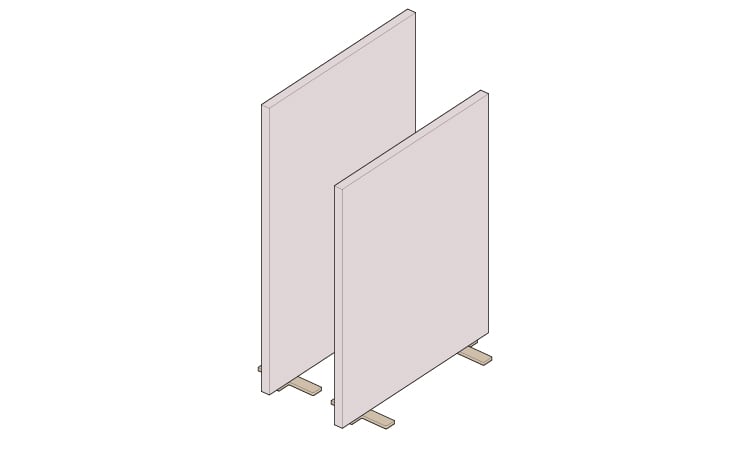

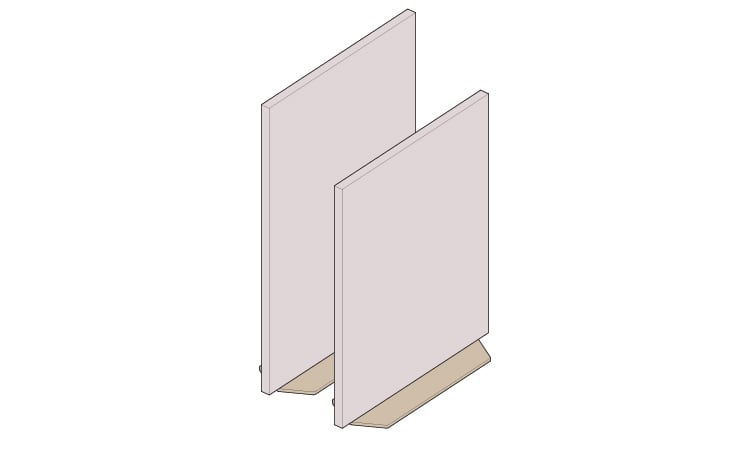

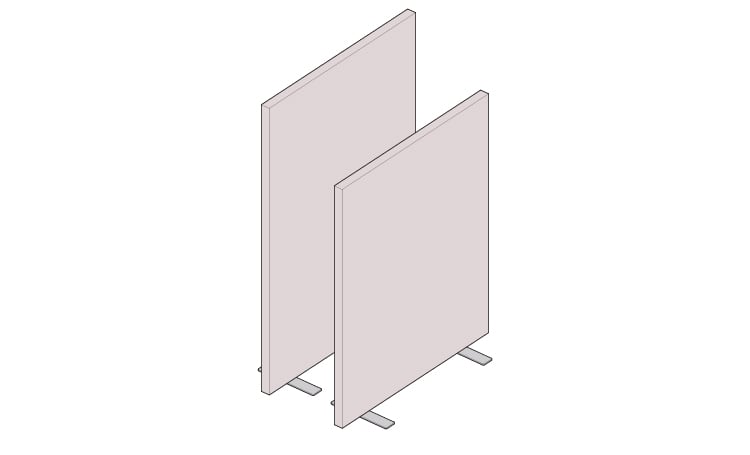

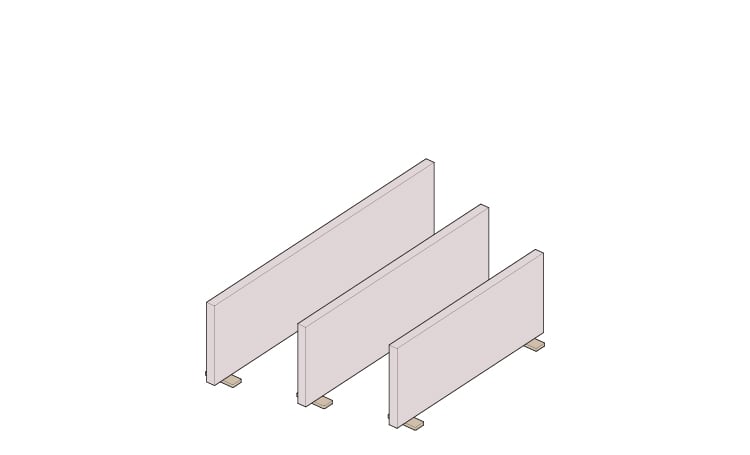

Kora acoustic screens

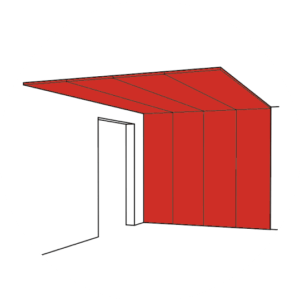

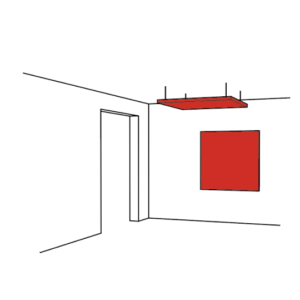

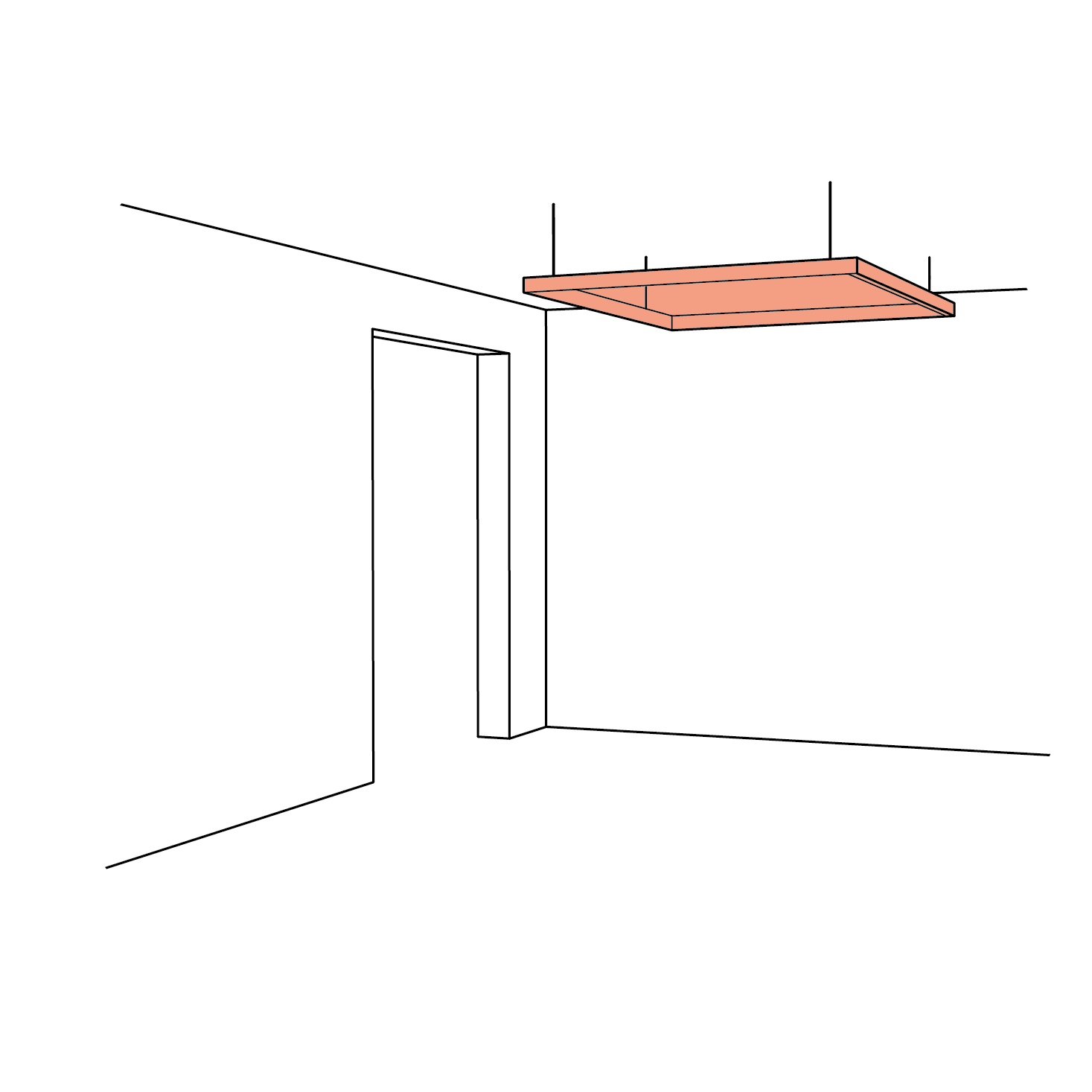

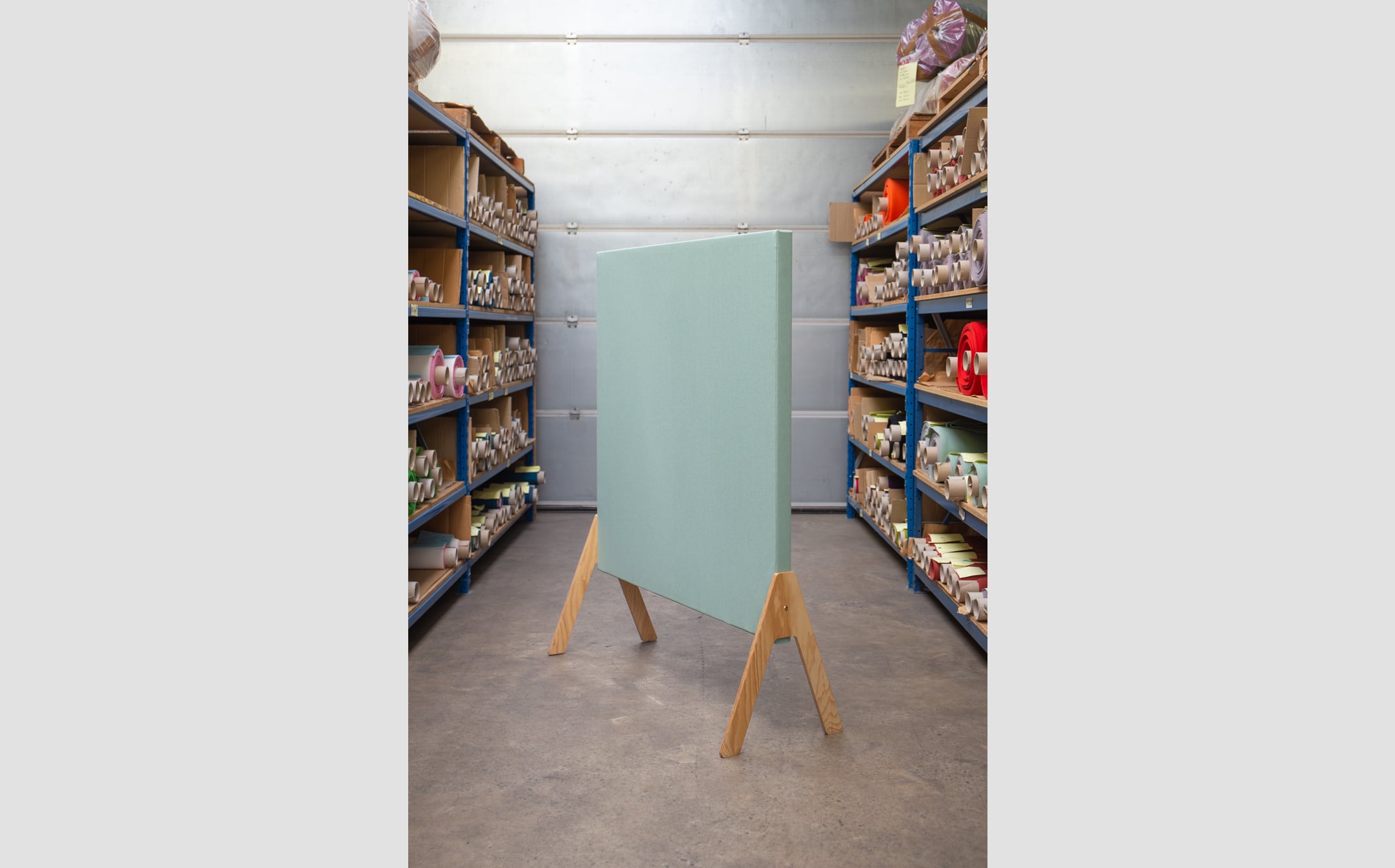

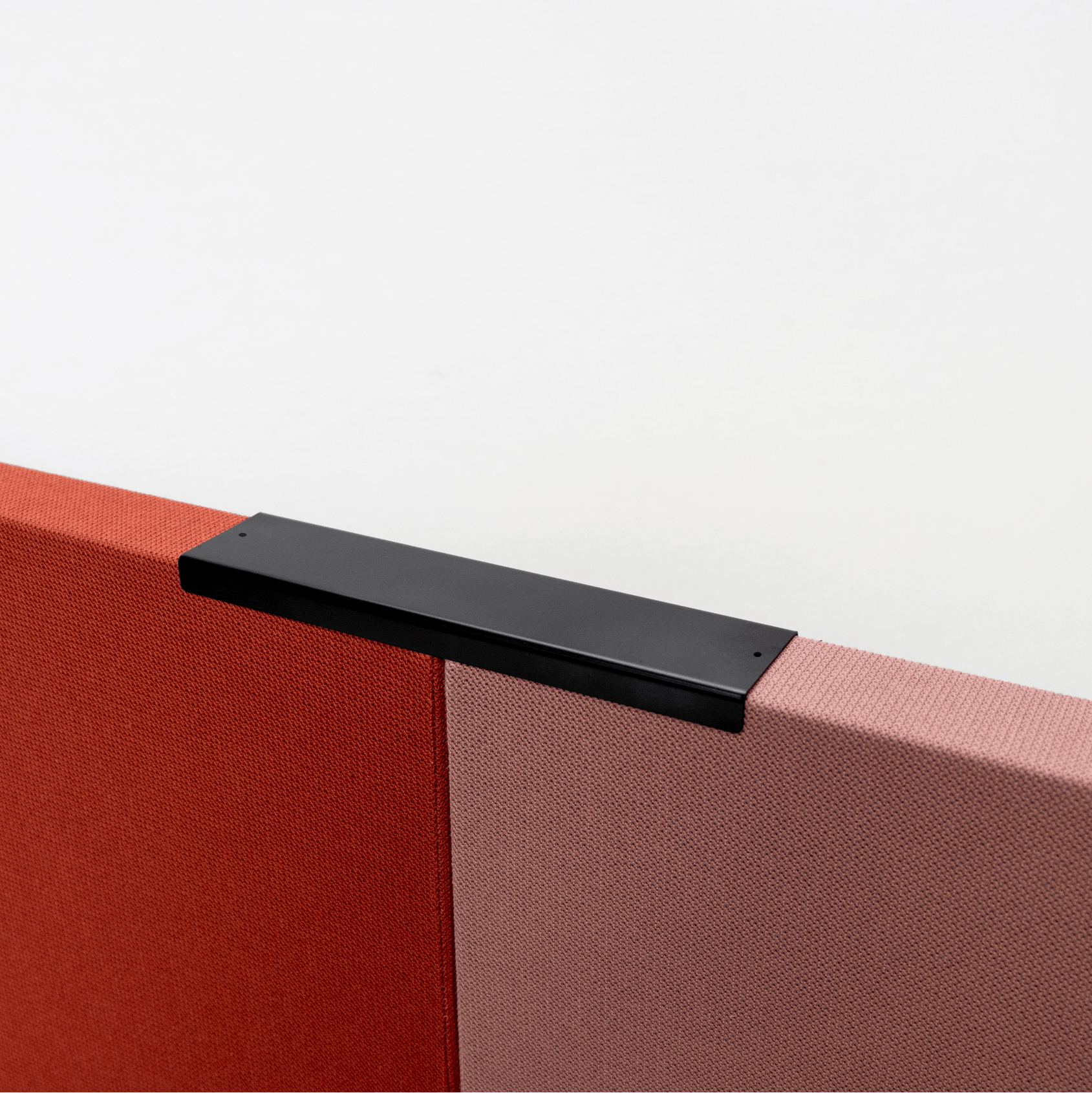

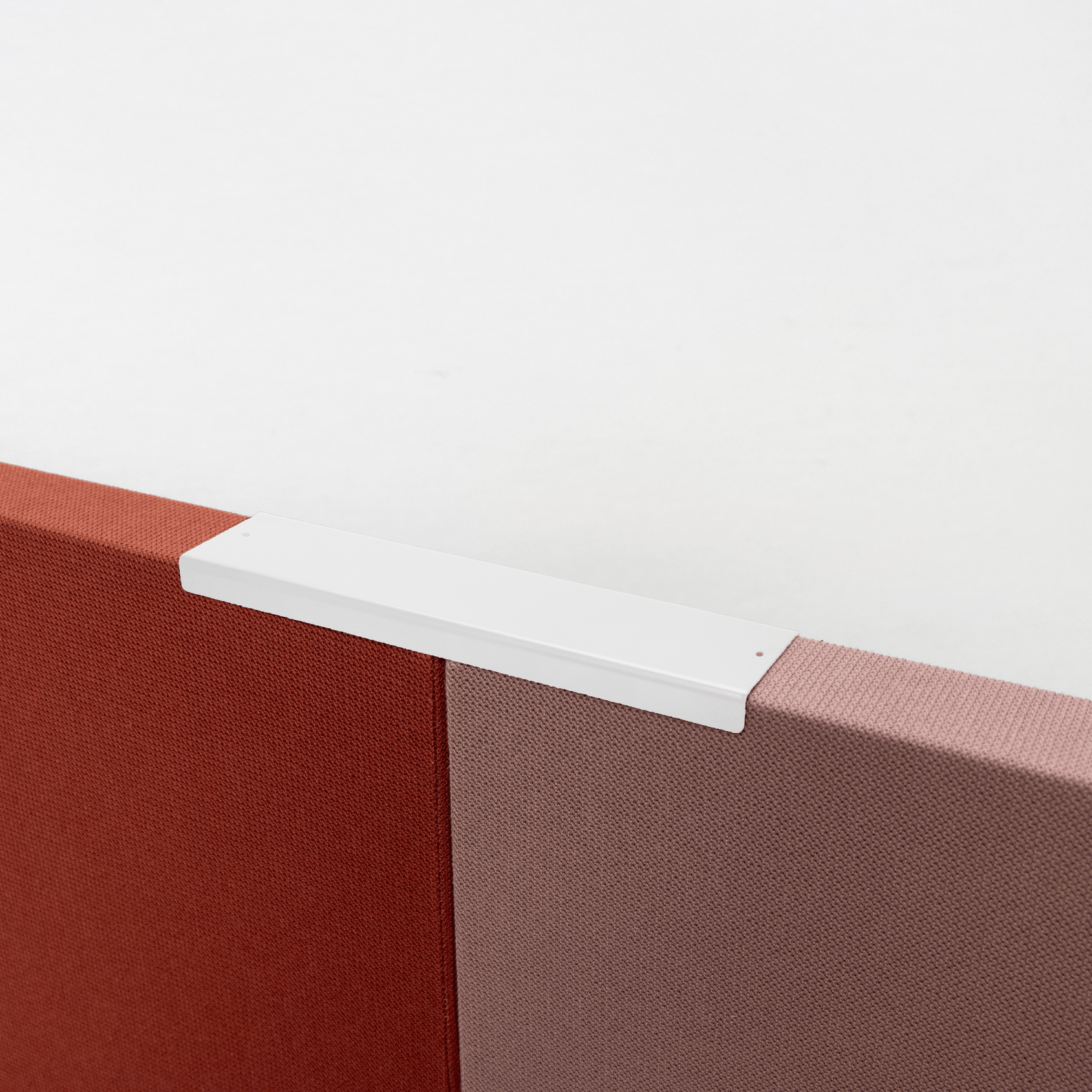

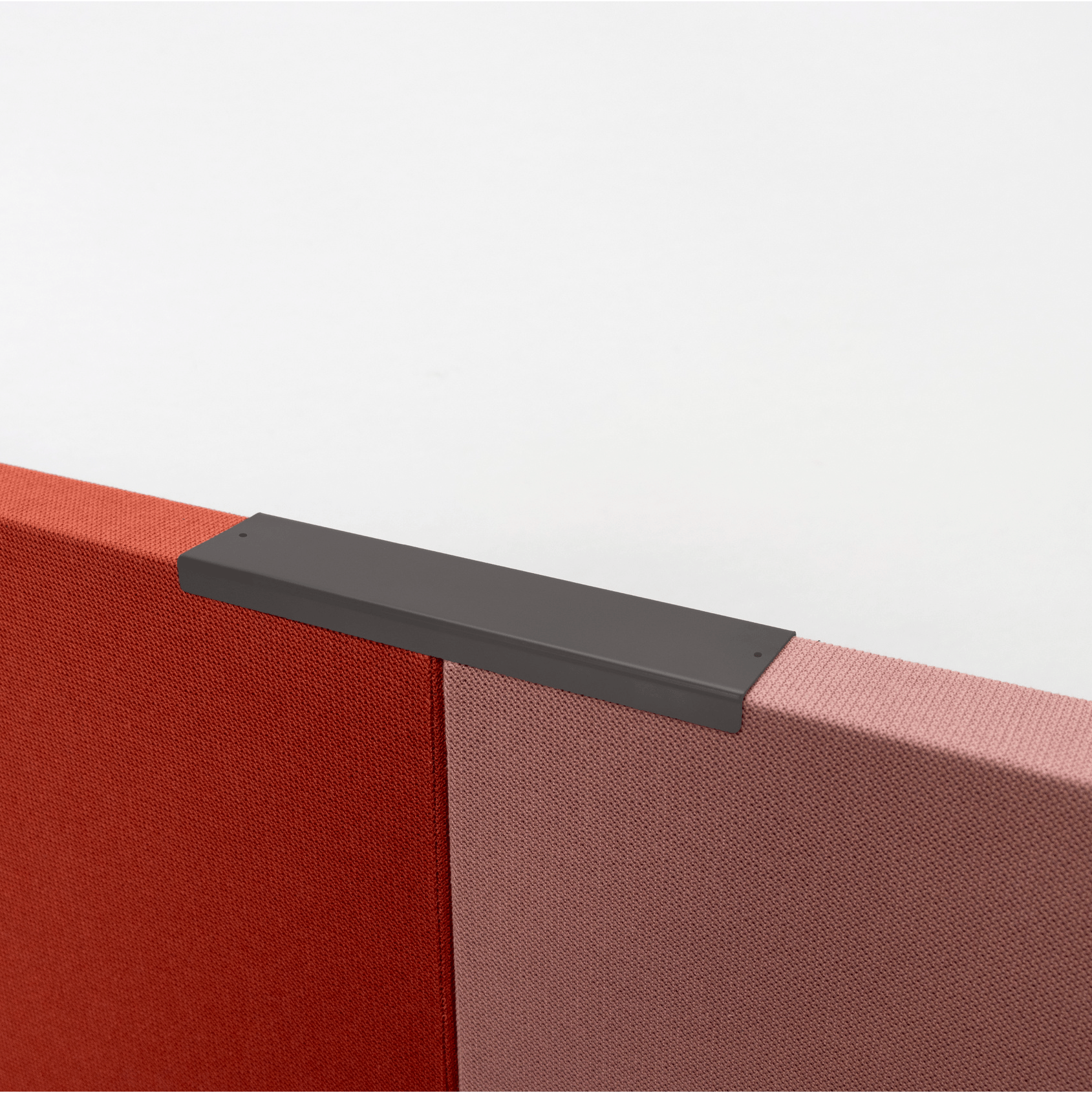

In shared spaces, Kora acoustic screens can be used to organise what is visible and what is not, and to control the acoustics around people so as to improve their individual comfort.

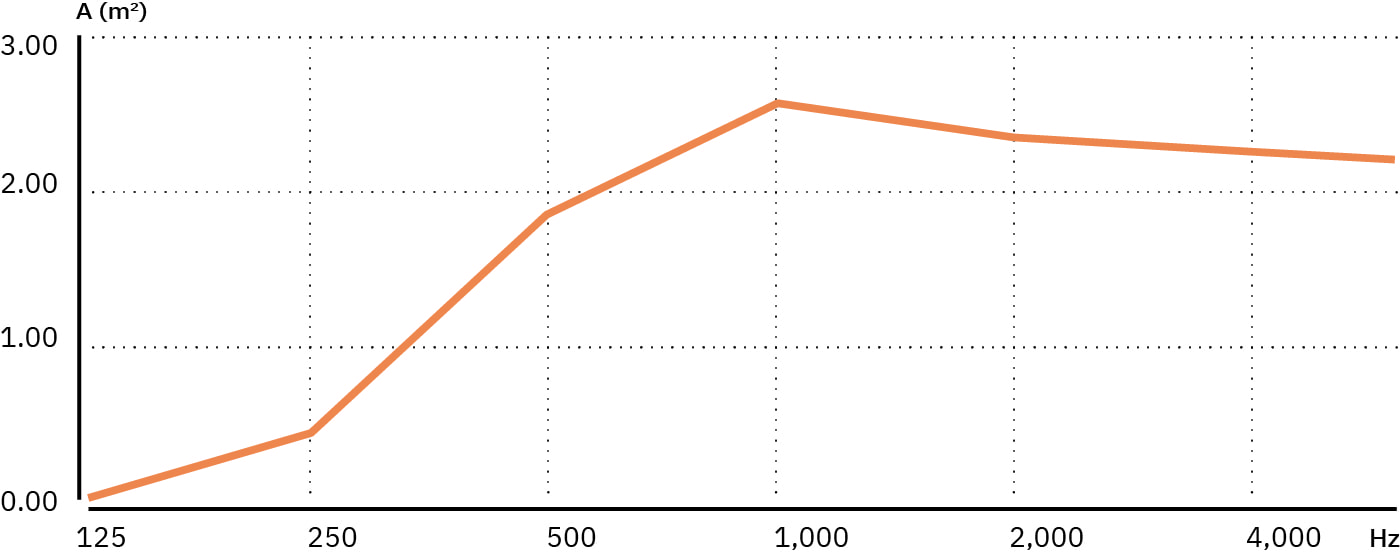

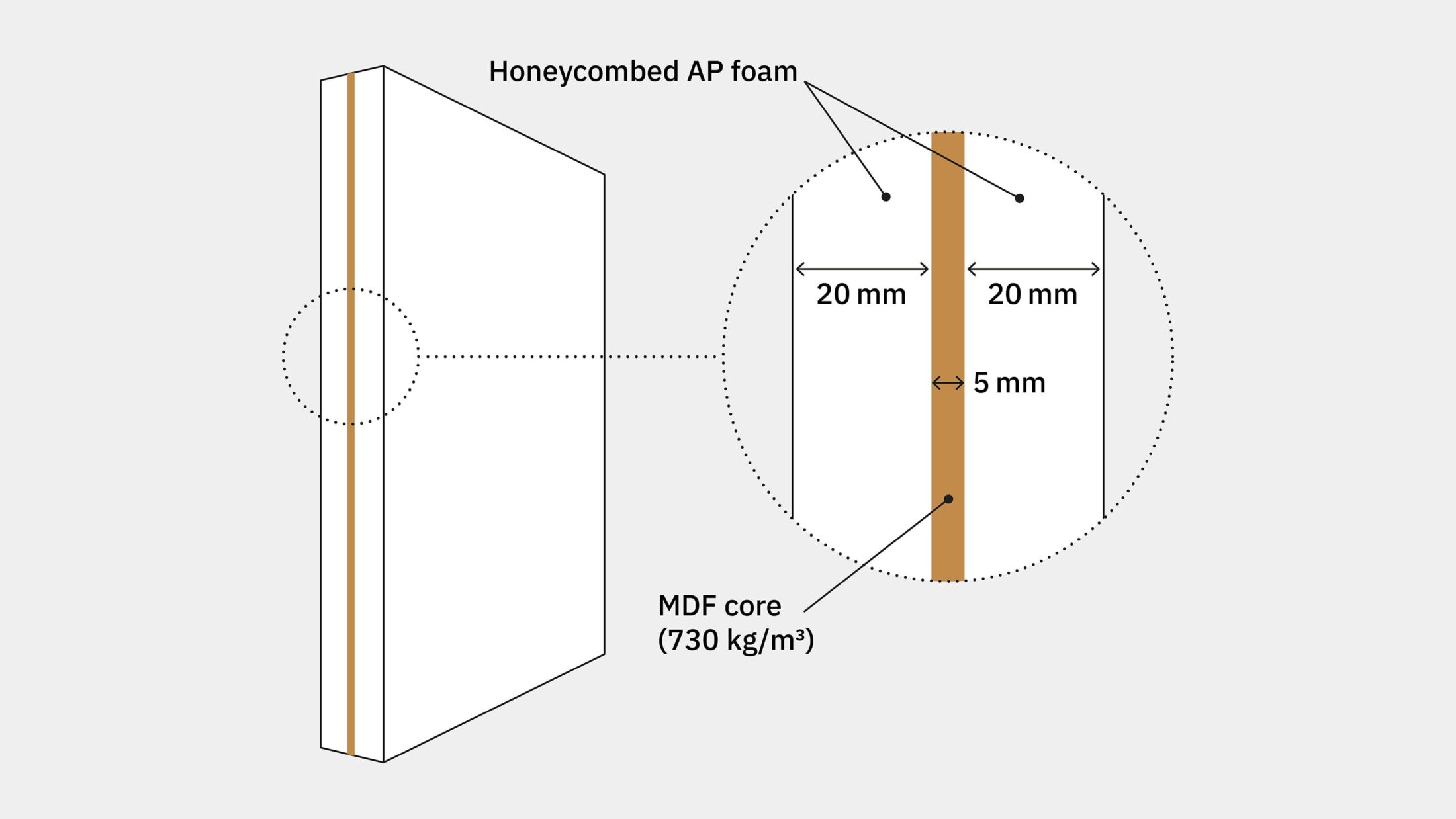

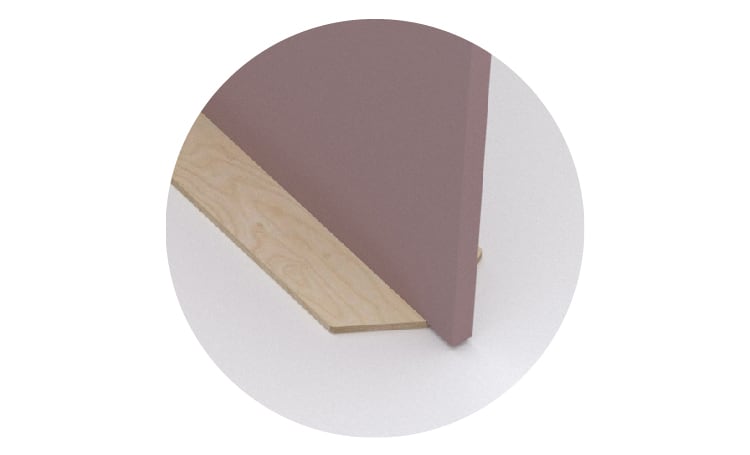

As well as reducing reverberation, Kora screens with their 5-mm-thick MDF cores also effectively dampen sound transmission.

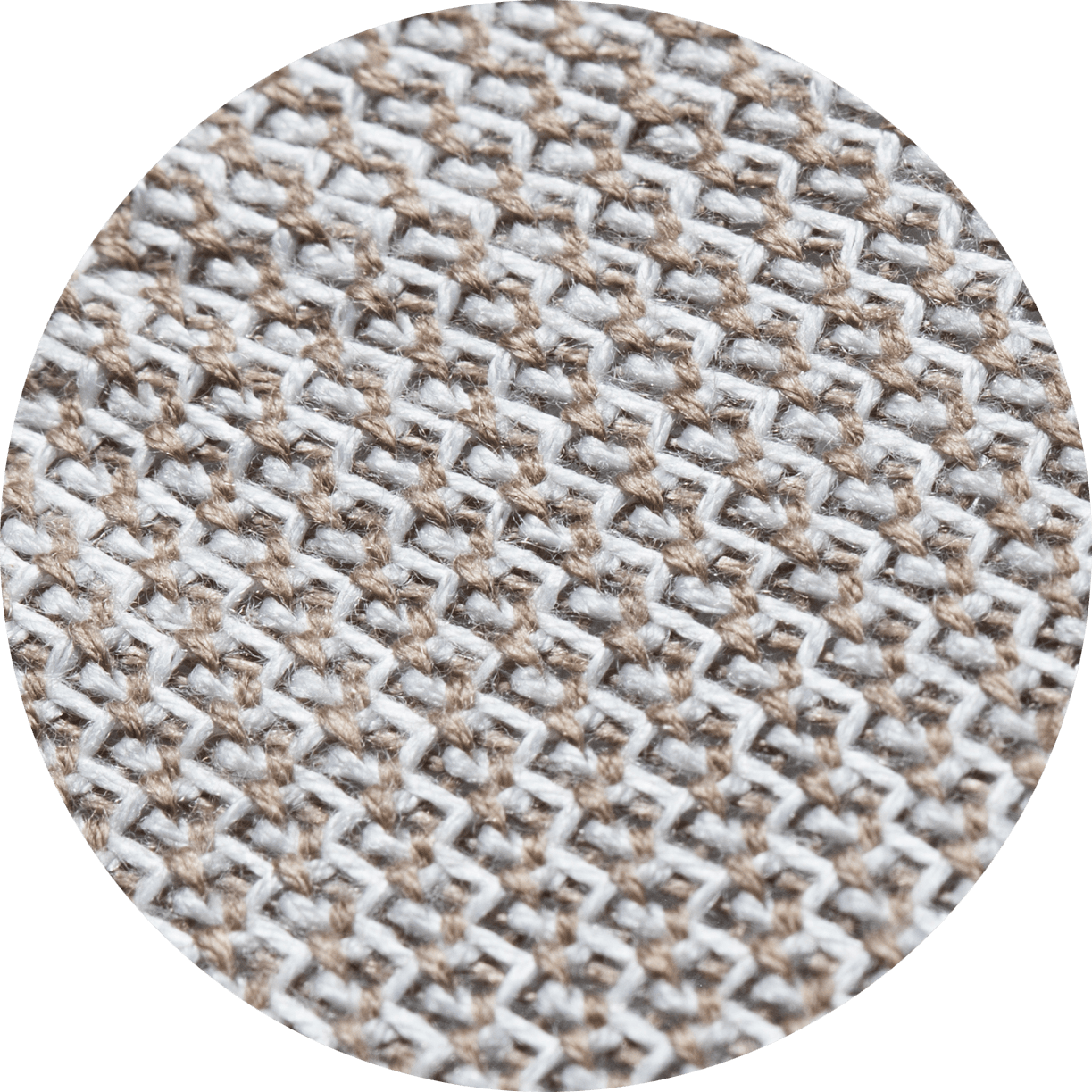

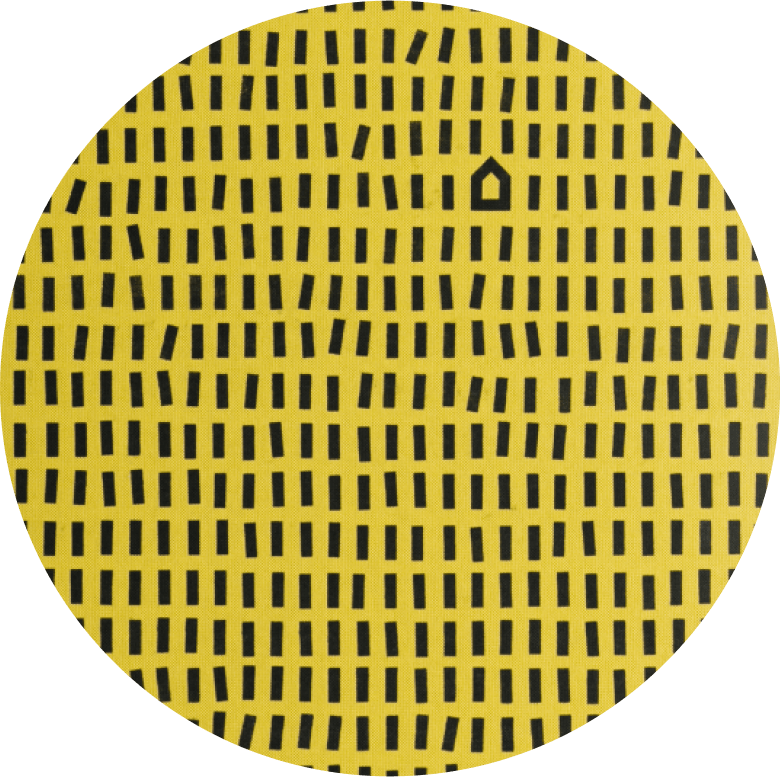

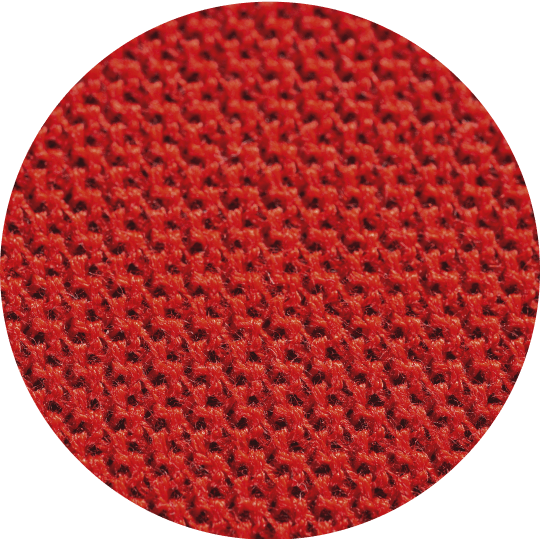

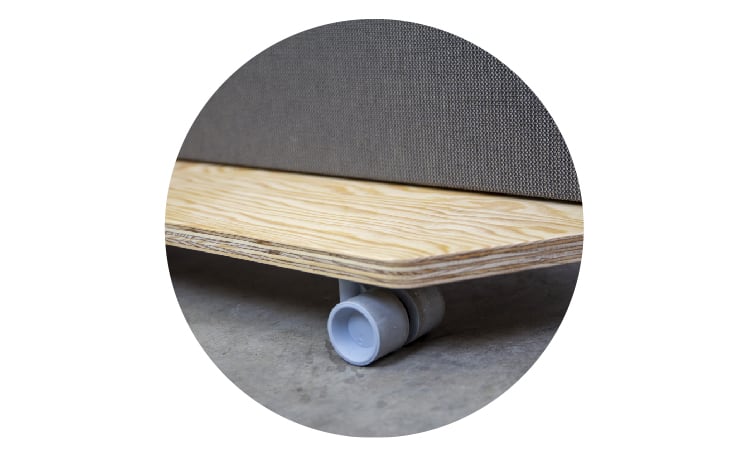

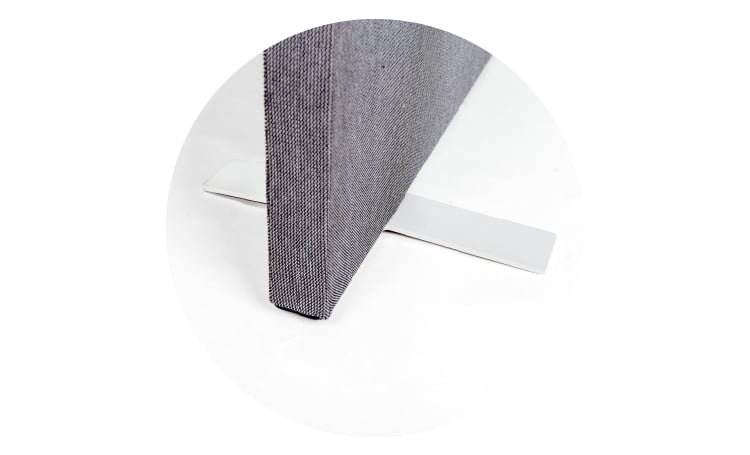

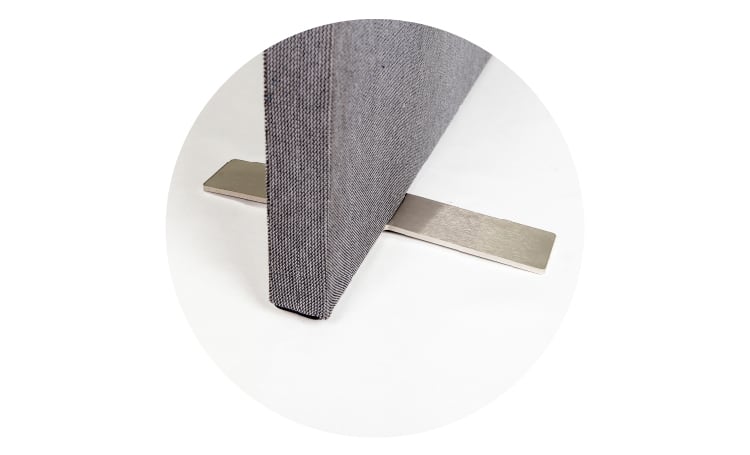

Their simple shape and robustness, the wide range of feet available and the 30 colours in the Aeria palette give designers a multitude of combinations to play with.